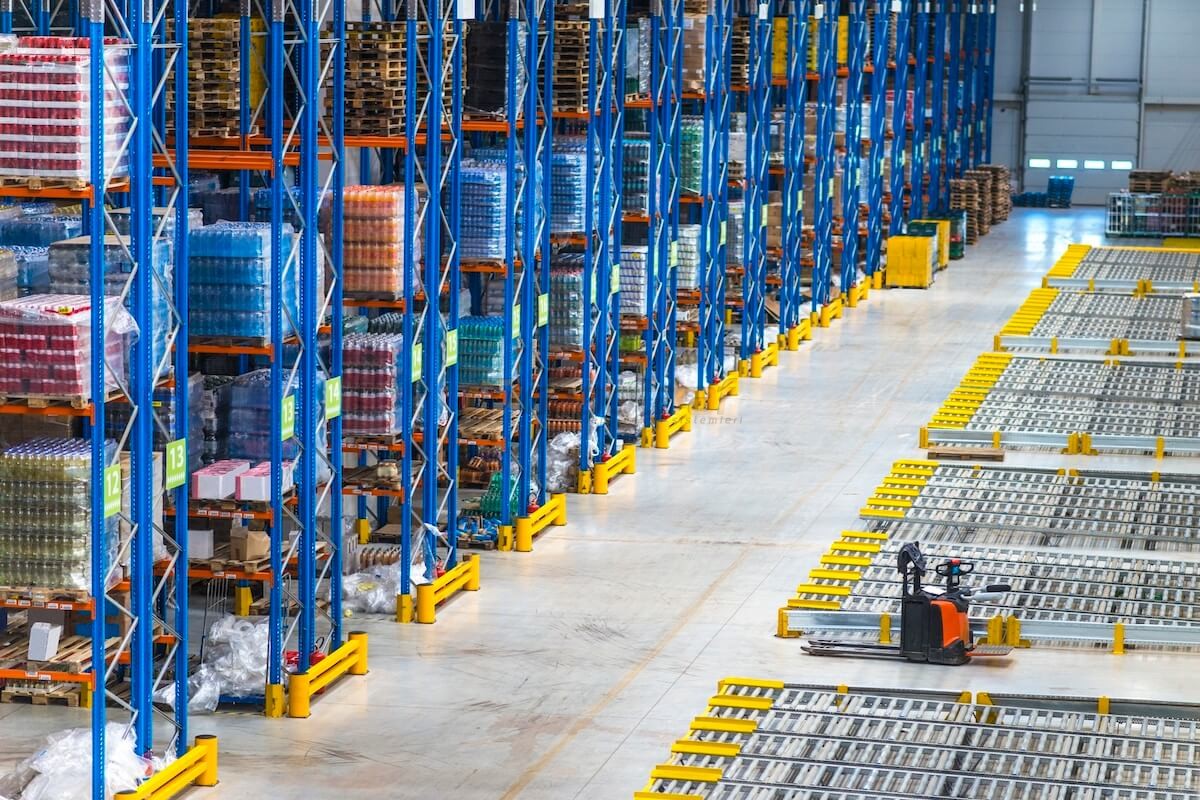

Mezzanine racking systems are multi-level racking solutions that allow you to use your existing warehouse or production area in the most efficient way. By creating additional storage floors in high-ceilinged areas, they increase the use of vertical space and provide cost savings to businesses. While expanding warehouse capacity, these systems also speed up operational processes and optimize logistics and stock management. Warehouse Racking Systems offer mezzanine racking systems designed specifically for the needs of businesses, providing maximum space efficiency and safe use.

Mezzanine racking systems made of durable materials enable the safe storage of heavy and light loads. Thanks to its steel construction structure, it offers long-lasting and robust use. With its modular design, it can be easily adapted to the needs of different sectors and expanded when necessary. Stairs, elevators or walkways can be integrated for access to upper floors, thus creating a safe and orderly structure in work areas. Mezzanine racking systems provide great advantages to businesses by offering ergonomic and efficient solutions that optimize warehouse management.

What are Mezzanine Racking Systems? What are the advantages?

Mezzanine racking systems are multi-storey storage solutions that allow maximum efficiency in existing space. They increase the use of vertical space by creating additional platforms in high-ceilinged warehouses and offer businesses extra storage space. Thanks to its modular structure, it can be customized according to need and expanded over time. Being able to be used both as storage and workspace makes mezzanine racking systems indispensable in many sectors. In addition to saving space, it optimizes work processes and makes logistics and inventory management more organized.

Working Principle of Mezzanine Racking Systems

Mezzanine racking systems are multi-storey racking systems built on steel construction platforms. While the main carrier columns provide a balanced distribution of the load, the upper floors can be used as various storage solutions or workspaces. Stairs, walkways or elevators can be added to access the upper floors. In this way, both the safe circulation of personnel is ensured and material transportation is facilitated.

The main purpose of these systems is to eliminate the need for horizontal expansion by using the existing warehouse height efficiently. Businesses can reduce their operational costs by expanding their existing areas without investing in a new warehouse. In addition, it can be integrated with special lighting and ventilation systems, thus making the working environment more comfortable.

For Which Warehouses and Businesses Is It Suitable?

Mezzanine shelving systems are an ideal solution especially for businesses that need large-volume storage. It is frequently preferred in logistics centers, e-commerce warehouses, automotive spare parts warehouses and the textile sector. It is also very advantageous for businesses with high-volume order traffic because it makes products accessible quickly and systematically.

In addition, it provides great convenience for factories that manufacture. Mezzanine systems increase efficiency by providing additional workspace for not only storage but also production processes. Many companies, from small and medium-sized businesses to large industrial facilities, can effectively manage their warehouse areas using these systems.

Differences and Advantages Compared to Standard Shelving Systems

Mezzanine shelving systems create much more storage space compared to classic shelving solutions. While standard shelving systems only use horizontal space, mezzanine shelves also utilize vertical space to create a multi-story structure. In this way, there is no need to invest in additional buildings to expand the warehouse area.

In addition, mezzanine shelves directly contribute to business processes. They support faster operations and more organized stock management. Thanks to their high carrying capacity, they allow heavy and bulky loads to be stored safely. They increase the efficiency of businesses by providing cost savings in the long term and make warehouse management much more systematic.

Mezzanine Shelving System Types and Technical Features

Mezzanine shelf systems are produced in different varieties according to the needs of businesses and warehouse structure. These systems, which differ according to the area of use, carrying capacity and assembly process, aim to maximize the storage efficiency of businesses. Varieties such as steel construction, modular and multi-story mezzanine shelf systems are preferred according to the physical characteristics and operational requirements of warehouses. While each system has its own advantages, their common points are space saving and regular stock management.

Mezzanine Shelving Systems with Steel Structure

Mezzanine shelf systems with steel structure are one of the most widely used shelf types with their high strength and long-lasting structure.Having a heavy load carrying capacity makes these systems ideal for industrial facilities, logistics centers and large-scale warehouses. Thanks to the durability of the steel material, it can be used safely for many years and is highly resistant to external factors.

These systems create extra floors by increasing the vertical use of the warehouse area. Thus, while making the best use of the existing space, they also help businesses reduce their costs. The durability provided by the steel construction allows the shelves to carry heavy loads, and can be shaped according to different warehouse needs with special design options.

Modular Mezzanine Shelving Systems: Flexibility and Easy Installation

Modular mezzanine shelf systems respond to the dynamic needs of businesses by offering the advantage of fast installation and easy portability. Thanks to its modular structure, it can be easily disassembled and reassembled when changes are required in the warehouse layout. This feature provides a great advantage especially for businesses in the growth process.

These shelf systems can be produced according to different load capacities with standard and special designs. Modular systems with light and medium load carrying capacity are a suitable option for e-commerce warehouses, businesses in the retail sector and small-scale industrial establishments. In addition, they offer a budget-friendly storage solution with their economical costs.

Increasing Storage Capacity with Multi-Storey Mezzanine Shelving Systems

Multi-storey mezzanine shelving systems are one of the most efficient space utilization solutions in high-ceilinged warehouses. Storage capacity is increased by creating second and third floors, thus businesses can expand their existing areas without making a new warehouse investment. Especially in sectors requiring intensive stock, effective use of vertical space provides a great advantage.

Security measures are of great importance in these systems. They can be integrated with stairs, railings and elevator systems to provide access to high floors. In addition, shelf arrangements can be customized in accordance with the operational processes of the business. Multi-storey mezzanine racking systems, which both expand the warehouse space and speed up operations, contribute to optimizing the logistics processes of businesses in the long term.

What to Consider When Choosing Mezzanine Racking Systems?

Mezzanine racking systems are an important solution preferred to increase warehouse efficiency. However, some basic criteria should be considered to choose the right system. Factors such as load capacity, material selection, physical properties of the warehouse area and long-term usage advantages play a decisive role in making the right decision. Choosing the most suitable racking system for the needs of businesses helps optimize costs and provide efficient warehouse management.

The Importance of Load Capacity and Material Selection

One of the most important criteria in mezzanine racking systems is load capacity. The carrying capacity of the shelves should be determined by taking into account the weight and volume of the materials to be transported. While steel construction systems are recommended for heavy loads, modular racking systems can be preferred for light and medium loads. Incorrect load capacity selection can increase the risk of collapse or deformation of the shelves, so engineering calculations should be done correctly.

Material selection is also an important factor affecting the durability and longevity of the system. Shelving systems made of stainless steel, galvanized coating or solid alloys are more resistant to impacts and external factors. For this reason, the most appropriate selection should be made by considering the warehouse conditions and the properties of the material to be used.

Determining the Right Mezzanine Shelving System According to the Warehouse Area

When choosing mezzanine shelving systems, the physical structure of the warehouse area should also be taken into consideration. Ceiling height, floor carrying capacity and mobility within the warehouse are critical factors in determining the right shelving system. For example, multi-story mezzanine systems may be more efficient for a high-ceilinged warehouse, while modular systems may be more suitable for areas with low ceilings.

In addition, the material flow within the warehouse and the use of equipment such as forklifts should also be taken into account. The layout of the racking system should be planned to increase operational efficiency and a safe working environment should be created within the warehouse.

Installation, Maintenance and Long-Term Use Advantages

Correct assembly and regular maintenance are of great importance for the efficient use of mezzanine racking systems in the long term. Assembly performed by professional teams increases the safety of the system and eliminates possible collapse or imbalance risks. In addition, the quality of the fasteners used during the assembly phase directly affects the durability of the system.

Regular maintenance is necessary to extend the life of racking systems and prevent possible failures.. Periodic checks should be made, especially in heavy load-carrying systems, and connection points and carrier columns should be inspected regularly. Considering the long-term usage advantages, quality materials and correct maintenance strategies provide cost savings to businesses and provide a safe working environment.